Why Lost Foam Casting is the Smart Choice for Foundries

Core advantages of lost foam casting for modern foundries

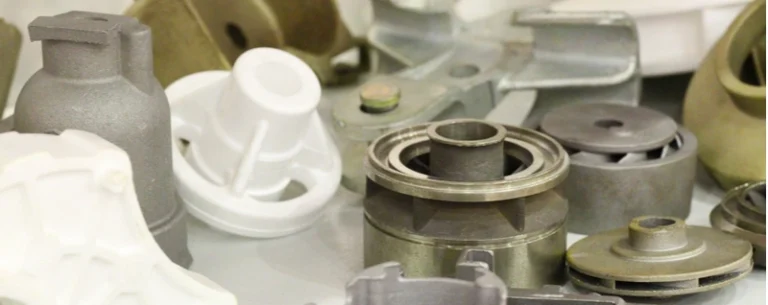

Lost foam casting is becoming a popular method among foundries because it offers many strong benefits. One key reason is that it reduces the number of steps in the casting process. There is no need to remove the pattern before pouring the metal, which simplifies the workflow. Lost foam metal casting produces a better surface finish, so less machining is needed afterward. This helps foundries save time and labor. Another big plus is its flexibility.

Whether you’re working with bronze, aluminum, or iron, lost foam casting can handle different materials. Foundries looking to offer new services can start with aluminum lost foam casting or branch into carbon steel lost foam casting or ductile iron lost foam casting. The overall process leads to lower waste and better accuracy, making it easier to meet strict quality demands.

Comparing lost foam vs traditional casting methods

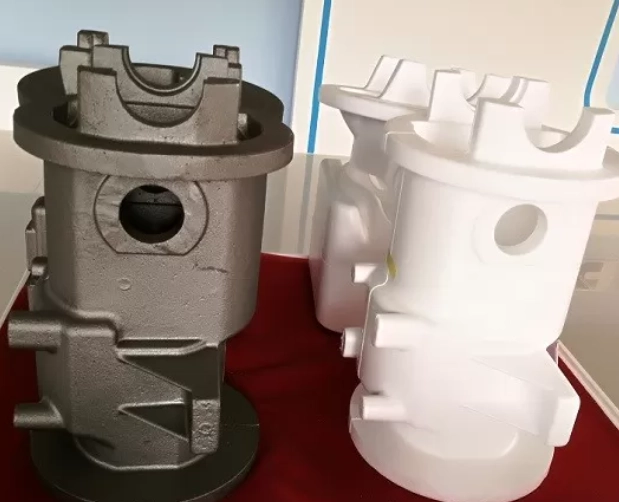

When you compare lost foam casting with traditional sand casting, the difference is clear. Traditional methods often need cores and molds that take time to prepare. Lost foam casting, however, uses foam patterns that melt away, allowing for more complex shapes and tighter tolerances.

This can be especially helpful for lost foam cast iron and gray iron lost foam casting, where design complexity can be a challenge. It also cuts down on post-processing work. With fewer steps and simpler tooling, the cost of lost foam casting becomes more predictable and often lower in the long run.

Market demand drivers for aluminum/iron lost foam components

Market demand is growing for parts made with lost foam casting, especially in industries like automotive, aerospace, and machinery. These sectors need strong but lightweight materials. That’s why aluminum lost foam casting is in high demand.

Iron parts, like those from gray iron lost foam casting or ductile iron lost foam casting, are also popular due to their durability. As customers look for better quality at lower costs, foundries that use this method can stand out. The need for better performance and design freedom continues to drive interest in lost foam casting manufacturer capabilities.

4-Step Cost-Effective Transition Strategy

Phase 1: Audit existing equipment for compatibility

Before making any big changes, foundries should first review what equipment they already have. Some machines and systems used for sand casting may also work for lost foam casting with small updates. Understanding current capacity helps reduce unnecessary costs.

Phase 2: Essential vs optional machinery investments

Not every piece of new equipment is needed right away. Start with the basics. Foam pattern systems and vacuum casting setups are essential. Optional upgrades like energy-saving air dryers or smart control units can come later. This helps lower the upfront cost of lost foam casting and keeps your investment manageable.

Phase 3: Staff training and process optimization

Changing to a new process means your team needs the right training. Lost foam casting pattern making and vacuum handling require specific skills. Offering workshops or working with experienced consultants will improve results and reduce waste early on.

Phase 4: Quality validation and production scaling

Before moving into full production, foundries should run test batches and inspect them carefully. Using quality checks at this stage ensures a smooth transition. Once the process is stable, it’s easier to scale up. You can start with small runs of alloy steel lost foam casting or bronze lost foam casting and expand as needed.

Critical Equipment for Lost Foam Casting Operations

Foam pattern creation systems

Lost foam casting starts with foam patterns, so a reliable system for making them is crucial. Horizontal or vertical PLC molding machines allow for precise and repeatable foam shapes. These machines work well with pre-foaming units that prepare the raw material and maturation solutions that strengthen the foam before use.

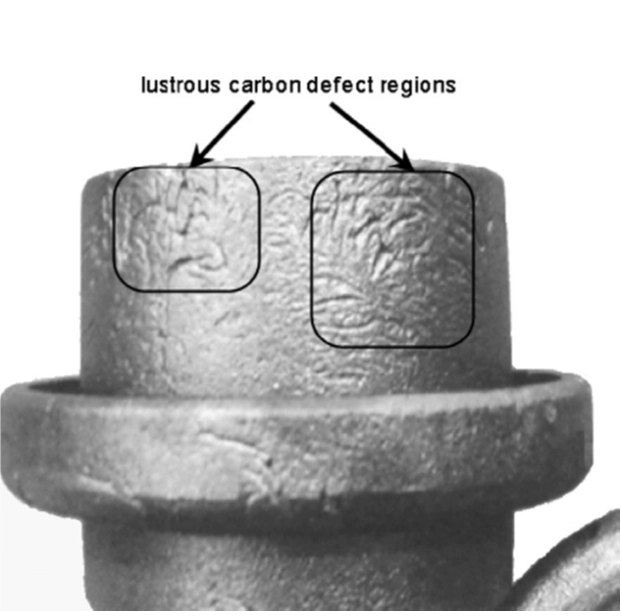

Pattern finishing technologies

After shaping the foam, it needs to be coated to hold up during the casting process. Lift-type paint mixers help create even coatings. Combined with efficient air dryers, they ensure the foam dries properly and doesn’t break down too early. This step is essential for both quality and safety.

Production-enhancing infrastructure

To manage the casting process well, foundries need the right environment. Central vacuum systems with smart controls help remove gases and keep the metal flow clean. Vacuum cooling units and heat recovery systems save energy and improve speed, reducing the overall cost of lost foam casting.

Material-Specific Applications & Profit Opportunities

Aluminum lost foam casting for lightweight components

Aluminum is ideal for parts that need to be light but strong. This makes it great for auto parts and electronics. Using lost foam aluminum casting lets foundries create complex shapes without adding weight, making their products more competitive in high-tech industries.

Iron implementations: Gray/Ductile iron advantages

Iron castings are still widely used in construction, agriculture, and heavy machinery. Lost foam casting works well for both gray iron lost foam casting and ductile iron lost foam casting, offering smoother surfaces and fewer defects. This cuts down on finishing work and saves money over time.

Specialty alloys: Bronze/Steel applications explained

For parts that need high resistance to wear or heat, specialty materials like bronze and steel are ideal. Bronze lost foam casting is great for valves and fittings. Alloy steel lost foam casting and carbon steel lost foam casting are used for tools and mechanical components. These materials bring in higher profit margins and allow foundries to serve more industries.

Cost Analysis: Maximizing ROI in Lost Foam Casting

Breaking down equipment vs operational costs

Lost foam casting needs some new equipment, but many operational costs are lower. For example, the simplified process and reduced labor can balance out the upfront machine costs over time. Carefully choosing the right setup helps speed up the return on investment.

3 proven ways to reduce pattern-making expenses

One way to cut costs is by using recycled foam for non-critical parts. Another is to improve foam cutting accuracy, which reduces waste. Lastly, automating parts of the pattern-making process can lower labor costs and improve consistency.

Long-term savings through energy recovery systems

Vacuum cooling and heat recovery systems reduce electricity use. These savings grow over time and make your foundry more eco-friendly. Foundries using such systems report better cost control and stronger profits, especially when making large volumes.

Partnering With Lost Foam Casting Equipment Experts

Hangzhou Ouchen Technology Co., Ltd (OC Technology) is a reliable manufacturer of lost foam casting equipment. Hangzhou Ouchen Technology offerings include various machines for the lost foam process, such as pre-foaming machines, foam molding machines, air dryers, and central vacuum systems, maturation silo, and lift-type paint mixers etc.

Hangzhou ouchen 기술 helps foundries shift to lost foam casting with less risk. Their engineers guide you through setup, staff training, and quality testing. This support helps avoid common problems that can delay production.

FAQs:

1. What’s the typical cost range for implementing lost foam casting?

The cost depends on the equipment and scale. Small setups can start from $50,000, while full-scale lines may cost over $300,000. The cost of lost foam casting becomes easier to manage with phased investments.

2. Can existing sand casting patterns be converted for lost foam?

Yes, with adjustments. Some pattern shapes can be reused, especially for simple parts. Others may need to be redesigned to fit the lost foam casting pattern making process.

3. How does lost foam casting improve surface finish for aluminum parts?

Lost foam casting produces smoother surfaces because the foam pattern melts away cleanly. This means fewer defects and less machining, especially for lost foam aluminum casting.

4. What maintenance is required for vacuum cooling systems?

These systems need regular cleaning and check-ups to keep filters and pumps in good shape. Most modern systems are designed for easy maintenance.

5. Which materials show fastest ROI in lost foam production?

Aluminum and gray iron lost foam casting usually show the fastest return because of high demand and lower material costs.

Ready to explore cost-effective lost foam casting solutions? Hangzhou Ouchen Technology’s lost foam casting machines are designed to help upgrade your foundry. 저희에게 연락하십시오 +86 1598479417 또는 zyh@oc-epc.com to discuss your transition roadmap.