What Are EPS Foam Block Molding Machines and Their Role in Lost Foam Casting?

Bridging the Gap Between Prototyping and Mass Production

EPS foam block molding machines are vital in lost foam casting. They offer a swift way to craft top-notch foam patterns. Unlike old-school mold-making methods, which are pricey and slow, EPS foam block machines let producers make exact foam molds quickly. These tools shine for small batches or test runs. They allow affordable trials without costly equipment.

Key Applications in Lost Foam Casting

EPS foam blocks serve many fields, like car-making, aerospace, and creative arts. Car builders use these machines to form light yet tough parts. Examples include engine blocks and gear pieces. In arts and sculpting, EPS foam block machines give creators a simple path to shape complex designs. These would be hard to cut by hand. The accuracy and steadiness of these machines make them essential for quality lost foam casting.

Why Traditional Methods Fall Short

Compared to hand-carving foam, EPS foam block molding machines provide better precision and reliability. Manual carving often leads to uneven results. This causes flaws in the final piece. Also, old ways can be tiring and sluggish. In contrast, foam block machines speed things up. They cut down on waste too.

Core Components of an EPS Foam Block Molding Machine

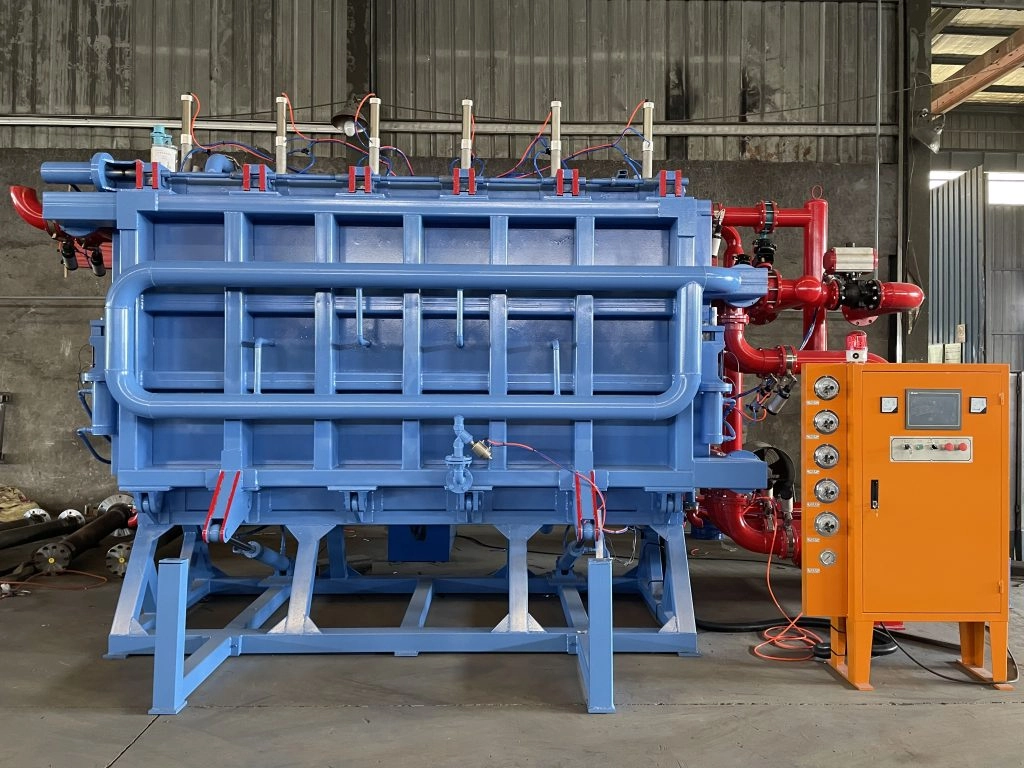

Structural Integrity: Welded Steel Frames and Heat-Treated Molds

The strength of an EPS foam block machine comes from its solid build. Top machines boast welded steel frames. These are treated to resist rust, ensuring long life. The molds get heat-treated too. This keeps them sturdy over time. So, they perform reliably even under tough pressure.

Advanced Steam and Cooling Systems

A big perk of EPS foam block machines is their smart steam and cooling setups. They use a three-valve steam system. This heats the foam block evenly. Plus, pulse cold-air cooling boosts energy savings. It shortens cycle times too. This makes the process quicker and greener.

Smart Automation: PLC and Touch-Screen Controls

Today’s EPS foam block machines come with programmable logic controllers (PLCs) and touch-screen panels. Trusted brands like Mitsubishi and Schneider offer dependable automation. Producers can manage material amounts, steam flow, and cooling phases precisely. This setup ensures steady quality. It cuts human mistakes too.

How EPS Foam Block Machines Work: From Raw Material to Finished Block

Step 1: Material Feeding and Pre-Expansion

The process kicks off with vacuum-aided feeding. This spreads raw EPS material evenly. Pre-foaming follows. It creates uniform thickness. This sets up a strong base for a great end product.

Step 2: Molding and Steam Penetration

Next, the molding starts. The material gets loaded in. EPS foam block machines use a special anti-7-shaped steam spread. This heats large foam blocks evenly. It stops warping. Plus, it ensures steady foam growth.

Step 3: Cooling, Demolding, and Quality Checks

After molding, the foam blocks cool down. Hydraulic ejection systems remove them smoothly. No damage occurs. Pressure gauges and auto-checks confirm each block meets standards. Then, it’s ready for casting.

Advantages of Using EPS Foam Block Machines in Lost Foam Casting

Cost Efficiency for Low-Volume Production

A top benefit of lost foam casting is its affordability. EPS foam block machines skip pricey molds. This lowers startup costs. Also, they reduce material waste. That makes small runs more budget-friendly.

Precision and Consistency

Automation ensures accuracy and repeatability in EPS foam block making. Advanced PLC controls help producers hit exact block sizes every time. This cuts down on casting flaws. The ability to make matching foam patterns boosts quality checks. It reduces hand fixes too.

Sustainability and Material Flexibility

EPS foam block machines aid green production. They can use recycled EPS material. This lowers environmental harm while keeping high standards. Mixing recycled and new materials offers flexibility. Producers can use resources wisely. They stay eco-friendly too.

Choosing the Right Foam Block Machine for Your Foundry

Critical Specifications to Evaluate

When picking an EPS foam block machine, check key details. Cycle time matters a lot. Most machines run 8–10 minutes per block. Plate size flexibility is another factor. It sets the biggest block size possible. Energy use should be checked too. This ensures affordable running costs.

Customization Options for Unique Needs

Hangzhou Ouchen Technology Co., LTD EPS Foam Plate Sheet Block Moulding Machines Customization Service offers great options. Ouchen’s machines have stepless encoder-controlled sizing. They adjust steam flow too. Producers can tweak block sizes via touchscreen. Their mixed heating and cooling ensures even curing. This works for big templates. Ouchen’s EPS foam block machines meet varied industry needs with tailored fixes.

Maintenance and Longevity Best Practices

To keep an EPS foam block machine lasting, regular care is key. Sand-treated frames fend off rust. Branded parts add toughness. Cleaning steam valves and checking hydraulic systems cuts downtime. These steps boost efficiency too.

Overcoming Common Challenges in Lost Foam Block Production

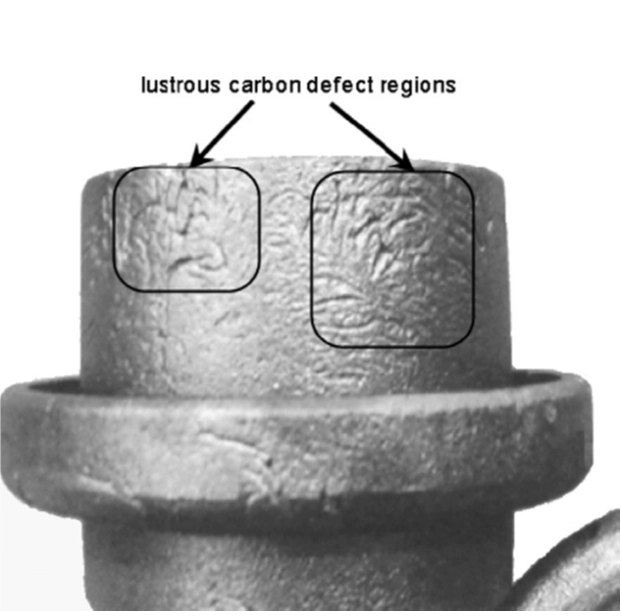

Avoiding Deformation and Density Inconsistencies

Foam block warping and uneven thickness can be fixed. Use vacuum-aided feeding and hydraulic locks. These ensure even growth and solid structure in the final block.

Solving Temperature Regulation Issues

Old cooling ways often cause uneven heat spread. This leads to block flaws. EPS foam block machines use pulse cold-air cooling. It speeds up cooling and keeps density even. This lowers internal stress risks.

Future Trends in Lost Foam Casting Technology

Integration with AI and Remote Monitoring

New tech like artificial intelligence and remote tracking is changing lost foam casting. Predictive care systems and live quality checks tie into PLC panels. Producers can tweak performance and stop breakdowns.

Eco-Friendly Innovations

Green goals stay a top focus in the field. Newer EPS foam block machines have closed-loop steam setups. They use more recycled material too. This cuts environmental harm. These advances match global pushes for cleaner production.

FAQs About EPS Foam Block Machines in Lost Foam Casting

- Can foam block machines handle both EPS and co-polymer materials?

Yes, many modern machines work with both EPS and co-polymers. This gives producers more options. - How does the hydraulic ejection system improve safety?

It ensures smooth block removal. This lowers injury risks for workers. It also prevents block damage. - What’s the maximum block size achievable with adjustable plate machines?

Adjustable plate machines make blocks in various sizes. They fit specific foundry needs. - How do these machines reduce energy consumption compared to older models?

New models use efficient steam and cooling systems. They save resources while keeping output high.

Elevate Your Lost Foam Casting Process Today

Ready to boost your test runs and small-batch work? See how Hangzhou Ouchen Technology Co., LTD’s customizable EPS foam block machines can save money. They improve accuracy too. Contact them at +86 15988479417 or zyh@oc-epc.com. Or visit https://www.oc-epc.com/ for a custom solution.