Lost foam casting is a new, highly advanced metal casting technology. If you are looking for lost foam casting machines, this article will serve as a complete guide to introduce you to the technology.

Definition and Basics

Lost foam casting or evaporative casting or EPS process is a specialized method of metal casting. It is a process in which a foam pattern, an exact replica of the finished metal part, is created. The foam pattern is generally created using expanded polystyrene, which is low in weight, easy to shape, and low melting point.

The foam pattern may be created by numerous operations such as cutting out a foam block, carving, or even injection-molding-type operations. After creating the foam pattern, the foam pattern is applied with a ceramic refractory coating. This coating serves two extremely important functions: it protects the foam from the sand that surrounds it in the mold frame and helps to create a smooth path for flowing molten metal in the casting process.

History of Lost Foam Casting

Lost foam castings have a history that dates back to April 1956 when H. F. Shroyer made a patent. Shroyer was proposing the use of foam patterns in green sand andutilizing it for metal casting. Shroyer developed EPS to be supported by cast shape with bonded sand. This new process was subsequently patented in 1958 and went on to form the foundation of what is today known as lost foam casting, or, more commonly referred to, the full-mold process.

How Lost Foam Casting Works

Pattern Manufacturing: The first operation in the lost foam process is the production of the foam pattern. As mentioned above, the foam pattern can be created through different methods based on part geometry complexity. Simple geometries would possibly simply be cut from a block of foam, while complex ones will require injection – molding – type operations.

Preparation of Mold: After the foam pattern is ready, it is placed in a mold box. Sand is compacted on either side of the foam pattern in the mold box, leaving a hole for the pouring of molten metal. The sand will keep the foam pattern in place as casting is done.

Metal pouring: After mold preparation, molten metal is poured through the passage as explained into the mold. When the heat molten metal comes in contact with the foam pattern, the foam vanishes immediately due to heat. This creates a void with the foam pattern shape that is occupied by the molten metal.

Finishing and Solidification: Molten metal is poured into the cavity, which solidifies into the finished metal part. When the metal cools and solidifies, the sand is expelled and the metal part is removed from the mold. The part can undergo additional processing through other finishing processes such as machining, polishing, or heat-treatment depending on its final application.

Advantages of Lost Foam Casting

Complex Geometry: Lost foam casting’s greatest advantage is that it can replicate even highly complex and intricate metal parts. Any other conventional casting process, i.e., sand casting or investment casting, can be tried with complex geometry to produce components. Lost foam casting as a better process can replicate even the most intricate foam pattern without any problem and thus replicate even complex outer geometries, thin walls, and internal voids in parts.

Less Material Waste: Since the foam pattern is burned out during the casting process, there is no need for a special core removal operation such as that of traditional sand casting. This creates less scrap material created, and lost foam casting is less expensive and more environmentally friendly.

High Accuracy: With the help of a highly accurate foam pattern that can be duplicated precisely, it ensures that the finished metal part will possess high dimensional accuracy. Consequently, lost foam casting parts will generally need less finishing and machining, thus saving money and time.

Simplified Manufacturing Process: The lost foam casting is a more straightforward manufacturing process than some traditional methods of casting. There is no necessity for assembly and disassembly of complex molds, and sand can easily be used as a mold material.

Applications of Lost Foam Casting

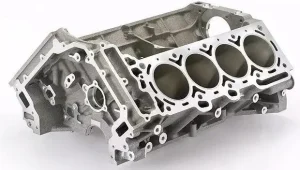

Automotive Industry: Lost foam casting is used in the automotive industry to produce various parts such as engine blocks, cylinder heads, and transmission parts. The capability to achieve complex shapes with accuracy makes it a popular choice among automobile manufacturers.

Aerospace Industry: Aerospace industry is also aided with lost foam casting. Components such as turbine blades, engine housing, and structural components can be manufactured with the required strength and precision using this process.

Marine Industry: Lost foam casting may be employed in casting propellers, hull hardware, and even engine components within the marine industry. Corrosion resistance to most of the metals employed within the marine industry and the accuracy that is guaranteed by lost foam casting render the process most agreeable.

General Machinery: Lost foam casting is utilized to manufacture gears, brackets, and other parts in general machinery where there is a need for special shapes and very high accuracy.

Hangzhou Ouchen Technology Co., LTD Lost Foam Casting Machinery

When it comes to a reliable lost foam casting machinery, there is no need to look further than Hangzhou Ouchen Technology Co., LTD. Hangzhou Ouchen Technology Co., LTD is a company that specializes in the manufacture of high-end intelligent lost foam casting machinery. They are experts in lost mold casting production, automation, and R&D. They manufacture foam molding machines, air dryers, and pre-foaming machines. Lift-type paint mixers and central vacuum systems are also supplied. Ouchen ensures high efficiency, low power consumption, and high quality through the use of German EPS/EPP technology with independent patents. They operate from the China concentrated EPS equipment manufacturing district. Contact them at +86 15988479417 or zyh@oc-epc.com.

Conclusion

Lost foam casting is an excellent technology with numerous benefits over traditional casting techniques. Its ability to achieve complex shapes, reduce material waste, and provide high-precision components has made it highly demanded by industries. Lost foam casting machines are the machines you need if you are searching for lost foam casting machines. Take, for example, the equipment provided by Hangzhou Ouchen Technology Co., LTD. Your knowledge of the lost foam casting theory and practice will lead you to the correct decision and take your metal casting business to new levels.