Lost foam casting, more commonly referred to as evaporative pattern casting, is one of the fastest-growing metal casting processes because of its design flexibility and capability to make parts geometrically very complex with very good surface finishes. In all cases, to achieve consistently superior results, control of every phase of the process is quite critical, and one of the most important yet usually undervalued steps is the drying of the coated foam patterns. If you aim at bringing your Lost Foam casting operation to full potential, buying a dedicated air dryer could be just that key that will unlock full performance.Let’s look in detail at some of the most powerful reasons why an air dryer can raise the bar for your lost foam casting process significantly.

Enhanced Coating Quality and Surface Finish

In lost foam casting, the foam pattern is coated with a refractory slurry that forms the mold cavity after the pattern is vaporized. The quality of this coating directly influences the surface finish and dimensional accuracy of the final casting.

Air dryers create a controlled drying environment that enables uniform application and consistency of the applied coating with limited possibility of the following: Cracking Peeling Irregular thickness Inclusions of trapped moisture

This careful drying process gives them a smooth, robust mold cavity that imparts superior surface finishes to your castings. This becomes of special importance in those cases where aesthetics appeal and close tolerances are required on applications, such as automobile parts, aeronautical machinery, and other minute sculptural works.

Faster Drying Times and Increased Throughput:

In any form of manufacture, time is money, and it isn’t any different in the lost foam casting. The usual ways of drying, either air or oven drying, are rather painfully slow and tend to bottle up one’s chain of production.

Air dryers speed the process of drying by the proper control of temperature and humidity conditions; optimizing the rate of moisture evaporation from the coating has several effects on drying time, much shortened times which thereby allow you:

- Increase production throughput

- Reduce lead times

- Meet tighter deadlines

- Respond more effectively to customer demands

The faster drying times ultimately will translate into increased productivity and profitability, making air dryers a worthwhile investment for any lost foam casting facility.

Improved Energy Efficiency and Sustainability:

In today’s environmentally sensitive world, manufacturers are keen to minimize environmental impact through reducing energy consumption.

Most modern air dryers employ heat pump technology, wherein the heat is drawn from ambient air and transferred to the drying room. This is significantly more energy-efficient than any conventional heating, such as electric or gas-fired systems.

Adding a heat pump air dryer into your lost foam casting operation can help you:

- Save on energy consumption

- Cut your operating costs

- Minimize carbon footprint

- Operate in conformance with sustainability goals

Reduced Defects and Improved Casting Quality:

The process of generating defects in castings, whether repairable or not, is very expensive and time-consuming, affecting the overall profitability.

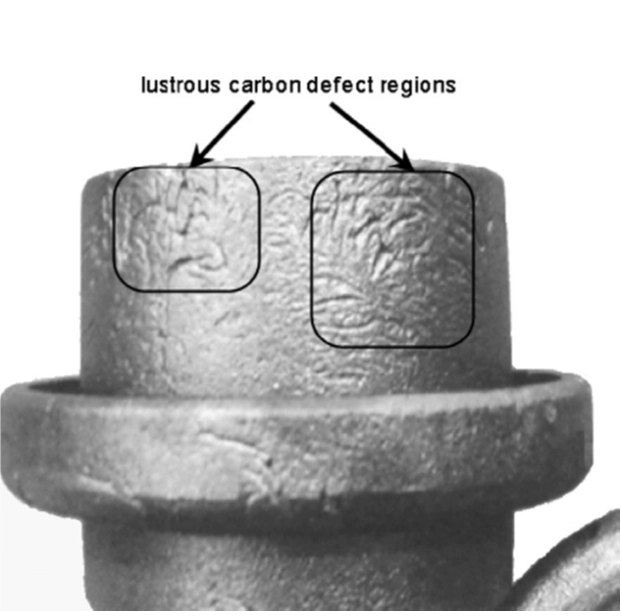

Moisture entrapped in the coating is a major culprit for casting defects, which includes blowholes, porosity, and other imperfections that could impact the structural soundness of your final product.

Air dryers remove moisture from the coating more thoroughly to assure uniformity without defects in the mold cavity.

This leads to:

- Higher-quality castings

- Reduced scrap rates

- Increased customer satisfaction

Safer Working Environment for Your Workforce:

Workplace safety should always be a matter of importance, and lost foam casting processes can pose certain risks to your workforce, particularly at the drying stage.

Traditional drying methods tend to employ open flames or high heat, creating risks of burns, fire, and fumes that can harm the health of your workers.

Air dryers remove these risks by creating a controlled, enclosed environment for drying.

This ensures:

- Reduced risk of burns

- Elimination of open flames

- Improved air quality in the working area

A safer working environment not only protects your employees but also reduces the risk of accidents and downtime, which overall contributes to a smoother and more efficient operation.

Hangzhou Ouchen Technology – Your Partner in Lost Foam Casting Solutions:

Ouchen Technology Co., Ltd. is the leading supplier of high-class intelligent lost foam casting machinery and continuously commits to bringing in pioneering solutions to raise efficiency, quality, and environmental friendliness into casting. Keeping in view that proper and efficient drying in the Lost Foam process holds the pivotal role, Ouchen proposes complete air dryers ranging in wide diversity and productions.

Now, let’s get into the details of their offering with respect to air dryers for applications and needs.

Top Mounted Air Dryers: These units are designed for space optimization, mounted directly atop the drying room. They have been fitted with efficient heat pump systems that ensure energy-efficient operation with precision temperature and humidity control for uniform drying.

Rear-mounted Air Dryers: It comprises powerful dehumidifiers with higher drying intensity to act in specific applications, which must develop very fast evaporation at low temperatures. Several options can be used to serve diverse drying room capacities when production volume is desired.

Indoor Air Dryers: A series of drying solutions wherein every unit integrates heat pump air energy, condensation, and heat recovery technologies in a multifaceted way for efficient heating, dehumidification, drainage, and waste heat recovery with high intensity of use and little harm to the environment.

Besides this advanced technology in air dryers, Ouchen stands out, satisfying customers by providing expert Consulting: Choosing the most suitable air dryer solution for your casting needs. Turnkey installation and commissioning services. Full after-sales service to ensure that your air dryer system operates correctly and at peak efficiency. With Ouchen, you are assured of high-quality, reliable, and technologically advanced air dryers to significantly improve your lost-foam casting process.

Contact Ouchen Today for a Tailored Solution:

Investing in an air dryer represents a strategic step that can change your lost foam casting operation for good: improvement of quality, efficiency, safety, and sustainability. For your particular drying needs, reach out today to Hangzhou Ouchen Technology Co., Ltd., and go through the different air dryer solutions available. The company’s team of experts will be glad to give personalized guidance in helping you choose the right air dryer for your needs in optimizing the lost-foam casting process and unlocking its full potential.