| Model | OC-CX-Y1210 | OC-CX-Y1512 | OC-CX-Y1815 | OC-CX-Y2318 | OC-CX-Y2822 |

| Working Table Size/mm | 1200*1000 | 1500*1200 | 1800*1500 | 2300*1800 | 2800*2200 |

| Itinerary/mm | 1500 | 1500 | 1500 | 2500 | 2000 |

Note: Customization is acceptable if there are special size requirements

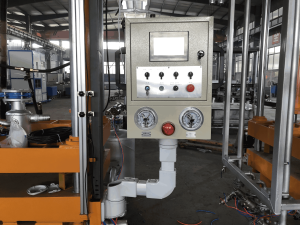

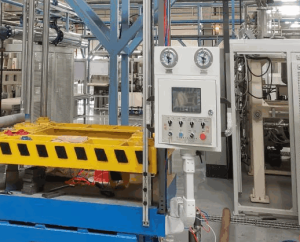

1、PLC computer control automatically completes a molding process. Computers have the function of automatically storing parameters during the molding process, establishing parameter databases for different product molding processes, making it easy to trace and analyze the molding process of each white mold. During the debugging process of equipment and new molds, experience and assumptions are not relied upon, and data speaks for itself;

|

|

2、The human-machine interface system of the molding machine has remote control function, free remote system upgrade and optimization; Equipped with remote debugging of device parameters, achieving no waiting after-sales service;

3、Adopting advanced concepts of “steam water separation, vacuum cooling energy recovery, and high-temperature demolding” technology to achieve efficient, energy-saving, automated production, intelligent control, and unmanned management;

|

|

(Water flooding cooling) (vacuum system)

4、The equipment includes a pressurized feeding tank, which has an automatic feeding function; The pressure tank adopts computer-controlled air proportional valve automatic adjustment to achieve constant pressure control and has over pressure protection function; Adopting top vertical multi-point automatic filling or zone grouping filling – uniform bead filling with small density gradient;

|

|

5、The molding machine has a mold cavity over pressure protection function and cooperates with the mold to actively exhaust during feeding

6、The template is made of Q325 steel plate welded together, and undergoes high-temperature heat treatment at 600 degrees to ensure that the steel plate is not easily deformed. After heat treatment, shot blasting and sandblasting are used to remove rust. The template is treated with hot-dip galvanizing for corrosion prevention, and the surface is painted

|

|