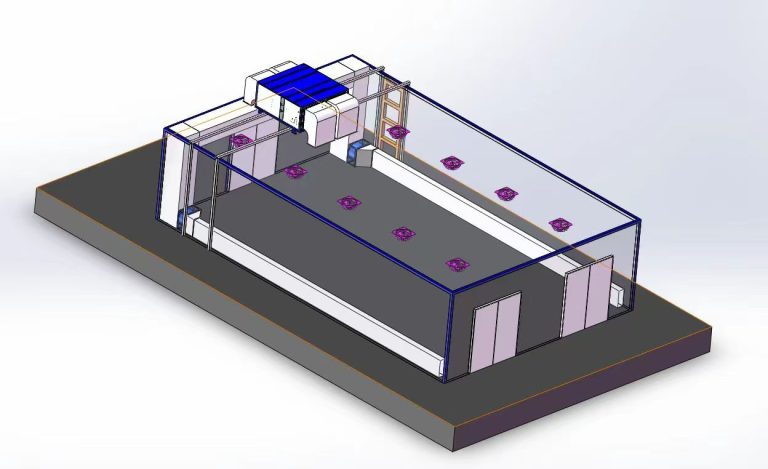

Our company’s research and development of disappearing mold dedicated air energy host adopts the currently most efficient air energy heat pump as the main heat source. This equipment is efficient, energy-saving, environmentally friendly, and zero emission. Compensated and improved the shortcomings of high energy consumption, low efficiency, and poor quality of traditional steam drying and electric heating units. At present, the white mold and coating drying unit dedicated to the lost foam casting industry have applied for multiple invention and utility model patents. And successfully developed multiple fast drying units suitable for different specifications of drying rooms.

| Air source heat pump drying and dehumidification integrated machine | Temperature and humidity control requirements | Adopting a disappearing mode dedicated air source heat pump drying and dehumidification integrated machine, the temperature can be adjusted freely between 35-60 ℃, the temperature difference in the room is less than 5 ℃, and the minimum relative humidity in the drying room can be controlled at 15% or below. |

| Dehumidification mode and heat recovery capability | The air source heat pump dryer adopts the most advanced open-loop and closed-loop integrated design, using a three-layer heat recovery mode. During the dehumidification process, the residual heat recovery rate is greater than 70%, which recovers the heat of the moisture in the drying room, removes the moisture, and only drains water without discharging heat. The COP is higher than 2.0 | |

| Human computer operation interface | Equipped with a visual LCD controller, the operation status, fault information, and process parameters of the drying room are clear at a glance. It is also equipped with an IoT remote module, which allows users to remotely manage and collect data on drying room operations through a mobile app. |